- Metal Fencing

- Gates

- Security Fences

- Pool Fences

- Metal Utility Fixtures

- Metal Sculpture

- Structural Metal

- Decorative Metal

- Metal Lockers

- Metal Doors

- Metal Window Frames

- Spiral Stairs

- Security Doors

Electrostatic painting is a technique that provides a fine sprayed finish to metal surfaces with a minimum of over spray and material waste.

Electrostatic is safe and environmentally friendly. Up to 98% of the paint is transferred to the surface, which means we use less paint, less solvents, and very little overspray compared to conventional and airless spray applications

This process is cleaner and faster than the usual way of on-site painting metal objects. Electrostatic painting can add more life and value to your wrought-iron pool or security fences, metal lockers, and security doors.

How Electrostatic Painting Works

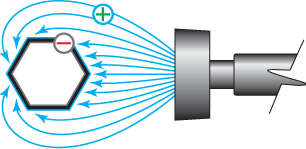

A high voltage charge allows a small stream of paint to be spun into a fine mist by the rotating disc at the end of this unusual spray gun.

The metal object to be painted is grounded and as the applicator completes the circuit by activating the gun, the static field transfers the paint to the object being painted. Without the electrical charge the paint would be flung all around.

The paint wrapping characteristics of this process often allow objects to be painted from one side with just one pass.

The paint wrapping characteristics of this process often allow objects to be painted from one side with just one pass.

On a typical pool fence ordinary spray applications require four or more passes from different angles and directions. With our method one pass covers 70% to 90% with the balance covered with a final pass. Varying designs and sizes require adjusting the application technique. But, this example shows the advantage of our electrostatic spraying system.

We are dedicated to excellence and to your satisfaction.

Call us for your indoor and outdoor decorative metal, security metal, and structural/utility metal painting needs. Let us quote on your metal painting project and put our decades of experience to work for you.

We are an Arizona licensed contractor and authorized as a general remodeling & repair contractor as well as a painting & wall covering contractor.

Electrostatic Painting FAQ

What is Electrostatic painting?

Electrostatic painting is an application method for applying certain specially formulated solvent based coatings.

Are there different kinds of Electrostatic sprayers?

Yes. Some are similar to airless paint sprayers, some are similar to conventional sprayers used for painting cars, and then there is the Ransburg #2. The Ransburg #2 is the machine that we use.

The first two use high hydraulic or air pressure to break up and atomize the paint.

The Ransburg uses a low pressure stream of paint dispensed into a rotating disc. The static charge that all the systems use turns the Ransburg’s paint into a fine mist.

They all benefit from a high voltage/low amperage electrical circuit, that includes the paint stream, collecting overspray and wrapping the paint around the object to be painted.

The Ransburg’s low pressure design allows for much greater overspray control and the ability to work in finished areas.

The answers below are based on the Ransburg machine and may not apply to the others.

Do you need to mask off around the areas you are painting?

Yes, the masking is minimal compared to other spray techniques. But, a breeze and/or gravity need to be taken into account. Also, things close to the work may be grounded and would attract the paint.

What can be painted with the electrostatic method?

Almost any conductive surface may be painted, using the right product.

Can you paint over an existing paint?

Yes, the existing paint must be clean and firmly attached to the surface to be painted. Any paint applied over an existing paint film will not go through the film and make it stick better.

Can you paint over any paint?

No, some latex or water based paints are lifted by the solvents or chemicals in the new paint film. There may be other situations where recoating would cause lifting. A test area is always a good idea.

Is painting over bare metal better than over existing paint?

Painting over a new surface would eliminate any problems that might arise in the two examples above. However, in an existing situation it may not be practical physically or financially to remove the old finish.

Can you touch up the finish?

The paint will touch as well or as poorly as it would if it was sprayed with any other method. There are methods we use to minimize touch up that needs to be done after spraying (see the question below). There is usually some touch up required after painting and the job conditions dictate what type of touch up (brush, roller, or spray) we use.

Will the paint get into all the corners, angles, and dangles?

No, tight corners and complex angles may not get a full coat of paint. Most of these areas are recognizable ahead of time and are addressed prior to finishing, reducing the need for touch up.

Why use an epoxy primer and what is it?

Epoxies have excellent adhesion and chemical resistance. Epoxy primers will stick to galvanizing. Most solvent based primers will not stick to galvanizing over the long term. Epoxy primer is made with epoxy resin and hardens primarily with a chemical reaction, unlike common paints that harden primarily by solvent evaporation.

What is catalyzed urethane?

Catalyzed urethane is a product that is made primarily from urethane resin. This product also hardens primarily by chemical reaction. Unlike the epoxies, it weathers very well and is used as a premium top coat.

As both of the above products “dry” by chemical reaction and not evaporation the over spray will stay wet longer and greater care is required in protecting the surroundings from overspray.